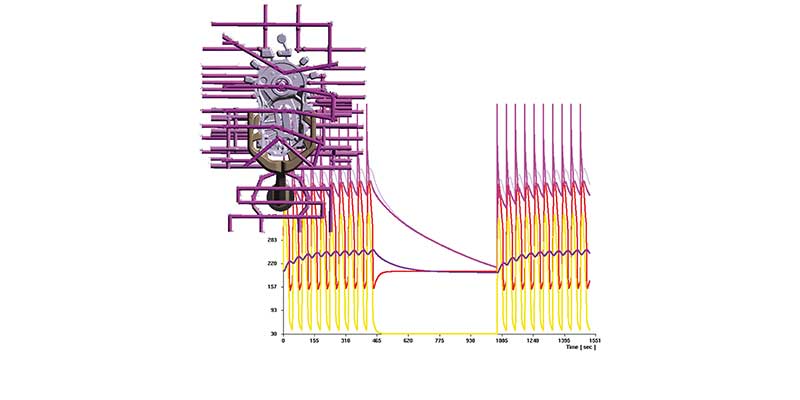

Equipment and procedure for real time X-Ray radiography of molten aluminum flow into permanent molds have been developed. The study also provides direct evidence on the filling pattern and heat flow behavior in permanent mold castings. The project highlights the characteristic features of gating systems used in permanent mold aluminum foundries and recommends gating procedures designed to avoid common defects. The main problems caused by improper gating are entrained aluminum oxide films and entrapped gas. It is evident that somewhat different systems are preferred for different shapes and sizes of aluminum castings. The approach taken was to determine how the vertical type gating systems used for permanent mold castings can be designed to fill the mold cavity with a minimum of damage to the quality of the resulting casting. The main goal of the project is to improve the quality of aluminum castings produced in permanent molds.

This report summarizes a two-year project, DE-FC07-011D13983 that concerns the gating of aluminum castings in permanent molds.

0 kommentar(er)

0 kommentar(er)